Working with precious metals in jewelry making is a time-honored craft that combines artistry with precision. This ancient skill involves using high-value materials such as gold, silver, and platinum to create stunning pieces of wearable art. Precious metals have a unique allure and intrinsic value that not only enhance the beauty of jewelry but also its investment potential. Understanding how these metals differ and how to work with them effectively can elevate your craftsmanship to new heights.

Precious metals are elemental substances that hold significant worth due to their rarity and desirable physical properties such as luster, malleability, and resistance to tarnish. These characteristics make them ideal for creating durable and beautiful jewelry pieces that can last for generations. Featuring prominently in various cultures and histories, precious metals continue to be highly sought after for both their aesthetic appeal and financial value.

In the jewelry industry, the selection of precious metals is crucial as it impacts the final look, durability, and price of the piece. Gold, for instance, comes in different karats which signify its purity and influence its color and strength. Silver offers options like sterling or fine silver depending on the project’s needs.

Other metals like platinum and palladium provide additional benefits such as extraordinary strength and hypoallergenic properties. By gaining a comprehensive understanding of these materials, jewelry makers can make informed choices that best suit their design objectives and target audience preferences.

Understanding Different Types of Precious Metals

When diving into the world of jewelry making, understanding the various types of precious metals is crucial. Gold, silver, platinum, and palladium each offer unique properties that impact durability, appearance, and functionality. These metals have been cherished throughout history not only for their beauty but also for their workability and lasting value.

Gold is perhaps the most renowned precious metal used in jewelry making. Available in several varieties based on karatage (such as 14K, 18K, and 24K), its color can range from yellow to white to rose gold depending on the alloys mixed with it.

Pure gold (24K) is extremely malleable but often too soft for everyday wear; hence it’s usually alloyed with other metals to enhance its strength without compromising its visual appeal. Understanding how to work with precious metals in jewelry making involves recognizing how different karats of gold will affect the final piece’s hardness and color.

Silver holds a prominent place in the jewelry industry due to its affordability and brilliant luster. Sterling silver (92.5% pure silver mixed with 7.5% other metals like copper) is more durable than fine silver (99.9% pure). Sterling’s robustness makes it ideal for creating intricate designs that need structural integrity. Knowing when to utilize sterling versus fine silver can drastically influence both the practicality and aesthetics of your creations.

Platinum and palladium are revered for their exceptional durability and hypoallergenic properties, making them perfect choices for sensitive skin or pieces subjected to daily wear, such as wedding bands. Platinum’s density provides a substantial feel while maintaining a naturally white sheen that doesn’t tarnish over time. Palladium, often considered an alternative to platinum due to its lighter weight and lower cost, shares many of these desirable qualities though it’s less widely known among consumers.

- Gold varieties: Pure (24K), 18K, 14K

- Silver types: Sterling Silver vs Fine Silver

- Platinum characteristics: Dense, durable

- Palladium benefits: Lightweight alternative

Understanding these distinctions helps jewelers select the appropriate metal conducive to their design requirements while aligning with consumer preferences and trends. Whether aiming for luxury with platinum or versatility with sterling silver, making informed choices enhances not only craftsmanship but also customer satisfaction in your jewelry creations.

Selecting the Right Precious Metal for Your Design

Choosing the appropriate precious metal for your jewelry design is a pivotal decision that influences not only the aesthetic appeal but also the durability and cost-efficiency of the final piece. When considering how to work with precious metals in jewelry making, it’s essential to weigh various factors such as hardness, color, and compatibility with gemstones.

For instance, gold comes in different karats and colors-such as yellow, white, and rose gold-each offering unique visual effects and physical properties that may or may not suit your intended design.

Durability is another crucial factor when selecting a precious metal. Gold’s malleability makes it easier to shape but also more prone to scratching compared to other metals like platinum. Platinum is known for its exceptional durability and resistance to tarnish, making it an excellent choice for pieces intended for daily wear, such as engagement rings or wedding bands. However, these benefits come at a higher cost, which might be prohibitive depending on your budget constraints.

Matching precious metals with gemstones involves considering both aesthetic harmony and structural integrity. For example, diamonds pair well with any type of gold or platinum because of their toughness and brilliance.

In contrast, softer stones like opal require settings that offer more protection; thus choosing a sturdier metal like platinum can provide additional security for these delicate gems. Staying attuned to market trends and consumer preferences can further guide you in making informed decisions that resonate with contemporary tastes while fulfilling practical requirements.

| Factor | Consideration |

|---|---|

| Durability | Gold: Malleable but prone to scratches; Platinum: Highly durable |

| Aesthetic Appeal | Gold variety colors (yellow, white, rose) vs. Platinum’s classic look |

| Compatibility with Gemstones | Diamonds suit all metals; Soft stones need sturdier settings like platinum |

| Cost Efficiency | Gold offers variation in price by karat; Platinum tends to be pricier |

Assessing these factors comprehensively will help you create jewelry pieces that are both beautiful and sturdy enough to stand the test of time.

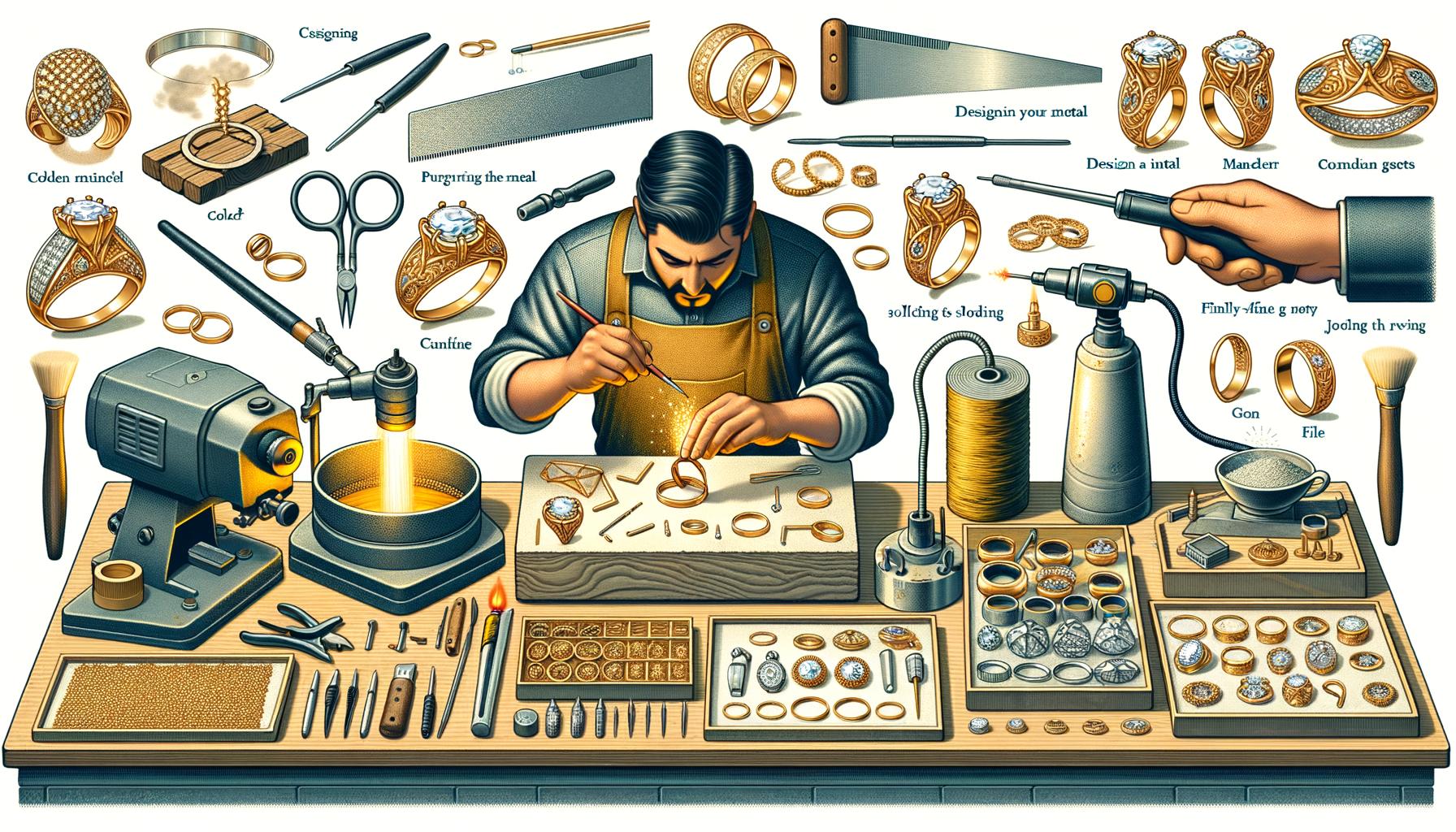

Essential Tools and Equipment for Working With Precious Metals

To embark on the journey of jewelry making, especially when dealing with precious metals, having the right set of tools and equipment is paramount. The foundation starts with basic tools that every jeweler should have in their workspace.

These include essentials like saws for cutting metal sheets or wires, files of various shapes and sizes for refining edges and surfaces, and hammers for shaping and texturing. Pliers are indispensable as they come in handy for bending and holding pieces while working on intricate details.

Besides these basic tools, advanced equipment becomes necessary as you delve deeper into how to work with precious metals in jewelry making. Soldering tools are crucial for joining pieces together; this includes a soldering torch, solder picks, flux, and various solder types (soft, medium, hard) that melt at different temperatures.

Polishing machines are another advanced tool that can significantly speed up the finishing process by providing a high polish to your metal creations swiftly. Casting equipment also becomes essential if you’re planning to produce multiple pieces or intricate designs efficiently through processes like lost-wax casting.

Safety in the workshop cannot be overemphasized when working with precious metals. Ensuring the availability of safety equipment like goggles to protect eyes from flying particles or intense light during soldering, gloves to handle hot items or chemicals safely, and properly ventilated spaces to avoid inhalation of fumes is crucial. Additionally.

fire extinguishers should be within reach to address any accidental fires promptly. By being well-equipped with both basic and advanced tools alongside proper safety measures, jewelers can achieve precision in their designs while maintaining a safe working environment.

Techniques for Shaping and Forming Precious Metals

Basic Metalworking Techniques: Cutting, Bending, and Annealing

When learning how to work with precious metals in jewelry making, mastering the fundamental techniques of cutting, bending, and annealing is crucial. Cutting involves using tools like saws to precisely shape metal sheets or wires into desired forms. Jewelers typically use jeweler’s saws for intricate cuts and shears for more straightforward tasks. Bending metal accurately requires mandrels or shaping pliers, which help achieve consistent curves without damaging the metal’s surface.

Annealing plays a vital role in preparing precious metals for further manipulation. This process involves heating the metal to a specific temperature to make it more pliable and easier to work with. Annealing softens the metal, allowing jewelers to bend and shape it without cracking or breaking. After heating, it’s essential to quench the metal in water to cool it down quickly while retaining its softened state.

Advanced Methods: Forging, Casting, and Die-Striking

For those looking to expand their skills beyond basic techniques, advanced methods such as forging, casting, and die-striking offer sophisticated options for working with precious metals. Forging involves hammering heated metals into defined shapes using anvils and stakes. This technique is excellent for creating custom textures and patterns on the surface of the jewelry piece.

Casting is another advanced technique where molten metal is poured into molds to create intricate designs that might be challenging to achieve through other means. Lost-wax casting is particularly popular among jewelers because it allows for high levels of detail and precision. The process begins by carving a model out of wax, encasing it in plaster or ceramic material, then melting away the wax leaving a cavity into which molten metal can be poured.

Die-striking involves pressing or stamping metal sheets between two engraved dies under immense pressure, producing precise and repeatable designs perfect for mass production or creating detailed components that are hardier than those made by other methods.

Precision Tips: Achieving Detail in Your Designs

Achieving precision in your designs is essential when working with precious metals; attention to detail can significantly elevate the quality of your jewelry pieces. One effective tip is maintaining sharp tools; dull saw blades or worn-out files can lead to rough edges or uneven cuts that detract from your design’s overall appearance.

Another key element is measuring twice before making any cuts or bends-meticulously planning ensures each component fits together seamlessly in the final assembly. Using calipers for exact measurements can make a substantial difference in achieving consistency across multiple pieces.

Lastly, practice makes perfect when developing an eye for detail in your work. Regularly practicing advanced techniques such as engraving allows you to intuitively gauge pressure levels needed for various effects while ensuring clean lines throughout your design-critical steps on how to work with precious metals in jewelry making exceptionally well over time.

Soldering and Joining Precious Metals

In jewelry making, soldering is a critical skill that involves joining two or more pieces of metal together by melting and flowing a filler metal into the joint. The success of this process is essential for creating durable and aesthetically pleasing jewelry.

Soldering requires precision and practice, as well as an understanding of the various types of solder available. Soft solder melts at lower temperatures, making it suitable for initial joins, whereas medium and hard solders are used in sequences to create intricate designs without previous joints melting.

The key to successful soldering lies in preparation. Cleanliness is paramount; both the pieces to be joined and the solder itself must be free of oils, dirt, and oxidation. This can be achieved through proper cleaning methods such as ultrasonic cleaners or chemical solutions like pickle solutions. Additionally, flux-a chemical cleaning agent-is applied to the pieces before heating to prevent oxidation during the heat application process. Flux also helps the solder flow more smoothly into the joints.

Safety cannot be overlooked when learning how to work with precious metals in jewelry making, particularly during soldering processes where high temperatures are involved. Proper ventilation is essential to avoid inhalation of potentially toxic fumes released during heating. Safety equipment such as heat-resistant gloves, safety goggles, and aprons should always be worn to provide protection against burns and other injuries.

| Type of Solder | Melting Point Range |

|---|---|

| Soft Solder | 361°F – 421°F (183°C – 216°C) |

| Medium Solder | 577°F – 618°F (303°C – 326°C) |

| Hard Solder | 713°F – 1425°F (379°C – 774°C) |

Finishing Touches

Polishing and texturing are critical steps in jewelry making, as they significantly influence the final appearance and value of the piece. Whether you’re working with gold, silver, or platinum, understanding how to apply these finishing touches can elevate your work from amateur to professional-quality. Here we will delve into various methods for polishing precious metals, along with techniques for adding texture to enhance the visual appeal of your designs.

Methods for Polishing: Hand Polishing vs. Machine Polishing.

When it comes to polishing precious metal jewelry, artisans have two main options: hand polishing and machine polishing. Hand polishing involves using specialized polishes, cloths, or brushes by hand to achieve a smooth finish. This method allows for precise control and is ideal for intricate designs where attention to detail is paramount. However, it can be time-consuming and requires considerable skill.

Machine polishing is faster and often yields more consistent results across multiple pieces of jewelry. Tools like rotary polishers or bench-mounted polishing machines come equipped with different types of abrasive wheels that remove surface imperfections efficiently. Understanding how to work with precious metals in jewelry making includes knowing when to use hand polishing versus machine polishing techniques to achieve the desired result.

Adding textures can transform a simple piece of metal into a unique work of art. Techniques such as hammering provide a rustic, organic look by creating small dents across the surface. Engraving allows for more intricate designs by etching patterns directly onto the metal using sharp tools or lasers.

Etching is another effective way to add texture; it involves using chemicals or acids to eat away at select areas on the metal surface, leaving behind raised patterns that catch the light beautifully. Each technique requires its own set of tools and expertise but knowing how to work with precious metals in this context opens up endless design possibilities.

The finishing process doesn’t just improve aesthetics; it also enhances wearability and durability. A well-polished ring will feel smoother on the skin, reducing any risk of irritation while providing a lustrous shine that customers find irresistible. Texturing not only adds visual interest but can also help obscure minor flaws in stones or settings.

Proper finishing is vital because it speaks volumes about your craftsmanship and attention to detail-attributes highly valued in custom jewelry pieces. By mastering both polishing and texturing techniques, you ensure that every piece you create looks stunning while standing the test of time.

Protecting and Maintaining Precious Metal Jewelry

Maintaining the luster and quality of precious metal jewelry requires meticulous care and attention. One of the fundamental aspects is cleaning, which must be done regularly to prevent tarnish and buildup of debris. Jewelry pieces made from gold, silver, platinum, and other precious metals should be cleaned using specific solutions designed for each type of metal.

For instance, a mild soap solution works well for gold while a specialized silver cleaner is recommended for sterling silver items. Avoid using harsh chemicals or abrasive materials that can harm the surface of the metal.

Proper storage is equally vital in preserving the beauty of precious metal jewelry. Each piece should be stored separately in a soft cloth pouch or within compartments in a jewelry box to prevent scratches and tarnishing.

Humidity is particularly detrimental to metals like silver; therefore, placing silica gel packs or anti-tarnish strips in your storage containers can help minimize exposure to moisture. It’s also wise to store jewelry away from direct sunlight and extreme temperatures, which can cause fading or structural damage over time.

To manage tarnish and handle necessary repairs, understanding how to work with precious metals in jewelry making is beneficial. Tarnish removal solutions vary depending on the type of metal; for example, soaking silver items in a mixture of baking soda and water can be effective for lightly tarnished pieces, whereas professional polishing may be required for more severe cases.

Regular inspections are crucial; look out for signs of wear such as loose settings or weakened clasps that may need fixing by a professional jeweler. Preventative care extends beyond cleaning and storing-removing your jewelry before engaging in activities like swimming or heavy labor will also help maintain its condition.

Ethical Considerations and Sourcing Precious Metals

As the jewelry industry evolves, there has been a growing emphasis on ethical considerations and responsible sourcing of precious metals. Consumers are becoming more aware of the environmental and social impacts associated with mining activities and are demanding greater transparency from jewelers.

When learning how to work with precious metals in jewelry making, it is important to understand the significance of using materials that are not only beautiful but also responsibly sourced. This includes knowing where your metals come from and under what conditions they were extracted.

One way to ensure ethical sourcing is by choosing certified metals such as Fairmined gold or recycled precious metals. Fairmined certification guarantees that the gold was mined according to strict environmental, labor, and financial standards set by the Alliance for Responsible Mining (ARM).

This helps support small-scale miners who adhere to safe and sustainable practices while providing them with fair wages. On the other hand, opting for recycled precious metals minimizes the need for new mining activities altogether, significantly reducing the industry’s carbon footprint and environmental destruction.

Another crucial aspect is verifying that your suppliers adhere to recognized ethical standards and certifications. Organizations like the Responsible Jewellery Council (RJC) offer certifications that validate whether companies operate responsibly regarding human rights, labor conditions, environmental impact, and product disclosure.

By working with certified suppliers, jewelers can provide customers with assurance that their creations meet high ethical standards. Additionally, educating yourself on how to work with precious metals in jewelry making involves ongoing research into evolving sustainable practices and legislation within the industry.

Incorporating ethical considerations into your jewelry designs not only benefits the environment but also enhances your brand’s reputation among ethically-conscious consumers. By being transparent about your sourcing methods and actively promoting sustainability practices, you contribute positively to a more responsible industry standard-one piece of jewelry at a time.

Conclusion

Mastering the art of working with precious metals in jewelry making is a journey that combines knowledge, skill, and creativity. Understanding the unique properties of gold, silver, platinum, and palladium allows you to make informed choices for your designs.

Remember to consider factors such as durability, color, and cost when selecting your materials. As you grow more comfortable with these elements, you’ll begin to see how each metal can accentuate different gemstones and contribute to the overall aesthetic of your pieces.

Working with precious metals requires not just basic tools but also specialized equipment that enhances precision and safety. From cutting and bending to advanced methods like forging and casting, each technique you master will add a new dimension to your craft.

Soldering is another indispensable skill in jewelry making; creating seamless joints can elevate the quality of your work significantly. And let’s not forget about the finishing touches-polishing and texturing are essential for bringing out the true beauty of your creations while ensuring they stand the test of time.

Ethical considerations are increasingly important in today’s jewelry industry. By sourcing metals responsibly and embracing eco-friendly practices, you contribute to a more sustainable future without compromising on quality or beauty. This commitment not only enhances the value of your work but also resonates with ethically-conscious consumers.

The journey doesn’t stop here; learning how to work with precious metals in jewelry making is an ongoing process that thrives on continuous exploration and experimentation. Don’t hesitate to experiment with new techniques or seek inspiration from seasoned artisans.

We encourage readers to share their experiences and tips in the comments section below-your insights could inspire others on this rewarding path. Together, we can elevate our craftsmanship to new heights while honoring the timeless allure of precious metals.

Frequently Asked Questions

How Do I Get Started With Precious Metals?

To get started with precious metals, begin by researching the different types of metals available, such as gold, silver, and platinum. Understanding their unique properties and values is essential to making informed decisions. Next, find reputable dealers or platforms where you can purchase these metals safely.

It’s also wise to diversify your investment to mitigate risks, so don’t put all your money into just one type of metal. Additionally, consider storage solutions; precious metals need to be stored securely to protect their value. Finally, keep yourself updated with market trends and seek advice from financial advisors if necessary.

Can You Make Money With Precious Metals?

You can certainly make money with precious metals through various means such as trading, investing in physical bullion like coins and bars, or participating in related financial markets like ETFs backed by actual metal holdings. The key is understanding that the prices of these metals fluctuate based on market dynamics including demand-supply equations, geopolitical instability, and economic conditions.

To increase profitability, it’s important to buy at lower prices during market dips and sell when the prices peak. Having a long-term perspective often helps as precious metals have historically proven to be valuable assets over time.

What Is the Best Metal to Start Jewelry Making With?

For beginners looking to start jewelry making, sterling silver is often considered the best material to work with due to its affordability and versatility. Sterling silver is easier to manipulate than harder metals like gold or platinum, allowing for a smoother learning curve for novices trying out different techniques such as soldering or texturing.

It also provides a professional finish that can make even simple designs look sophisticated without a significant upfront cost. Additionally, because silver tarnishes more slowly compared to other metals like copper or brass, maintaining your pieces is simpler which adds an extra appeal for beginners in jewelry making.

Welcome to my jewelry blog! My name is Sarah and I am the owner of this blog.

I love making jewelry and sharing my creations with others.

So whether you’re someone who loves wearing jewelry yourself or simply enjoys learning about it, be sure to check out my blog for insightful posts on everything related to this exciting topic!