There are many different metals that can be engraved for jewelry, the most popular being gold and silver. Each metal has unique qualities that enable it to take an engraving in various ways. Gold is known for its malleability and is easily engraved into any type of design.

Silver also offers great potential as it takes detail very well and is less likely to warp with age. Stainless steel, platinum, brass, and aluminum are also options for engraving jewelry that offer more versatility in terms of decorative qualities.

Engravings on metal jewelry offer a unique way to personalize an item or create a special gift for someone you care about. An engraving can be as simple as a name or phrase, or can feature intricate designs such as scrollwork or geometric shapes.

Additionally, you can add gems and stones to create a truly eye-catching piece of metal jewelry. Not only does engraving add visual appeal, but it’s also a great way to demonstrate your commitment by inscribing heartfelt messages onto precious metals that will last forever.

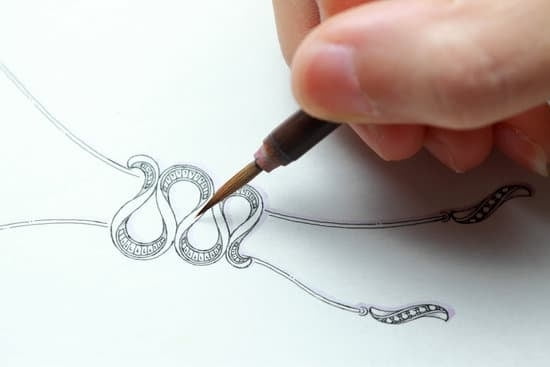

For those interested in learning how to effectively engrave on metal jewelry there are numerous tutorials available online or through professional courses at local arts centers where one can learn techniques from experienced craftsman. Engravers use specialized tools such as burin chisels and set gravers which allow them to work precise lines into the metals surface without damaging it further down the line.

Depending on the size and complexity of the desired design users may opt for either hand-held tools or larger machinery like diamond cutters or high-pressure carvings which provide detailed results within minutes instead of hours or days when hand tooling alone would be used.

Tools Needed for Engraving Metal Jewelry

- Jewelry engraving tool – power hand engraving systems are available for purchase, or the more cost effective manual handheld tool can be used.

- Carbide tungsten bits and burrs – different tips of these tools vary in size and shape available from hardware stores or specifically designed to work with engraving systems.

- Jewelry jigs – for larger items a jewelry jig can be used to guide the engraver along straight lines. This is essentially an adjustable grid system which will help the engraver create repeatable patterns and artwork designs.

- Metal stamps – metal stamps can be stored on their own or in wooden selections allowing for easier storage. Impressions created by metal stamps may require additional finishing touches.

- Cyber-optic laser etching machines – this type of machine allows for very precise etchings into metal surfaces from engravings to intricate artwork, logos, even photographs.

The Steps Needed To Engrave On Metal Jewelery

Step 1: Creating a template – this is necessary whether you use a powered or manual hand tool. It is recommended that the template should include all details necessary for achieving a perfect result. The template should also include measurements such as depth as well as font size and angle of lettering if required.?

Step 2: >Mounting the jewelry item onto your jig – Careful attention needs to be given to ensure that all measurements are exact so that each line is straight. The location of marks, holes and any notches should also be taken into consideration when creating the template.?

Step 3: >Engrave the jewelry item – Depending on what type of metal used choose the correct type of bit, burr or stamp to properly engrave your jewelry item accurately. When using manual tools take short strokes at a 45 degree angle for precision results. ?

Step 4: > Check that the markings are accurate with gauges – After every few strokes check that lines and curves are accurate enough using gauges such as calipers and micrometers. Damaged pieces can easily cause inaccuracies so use magnifying glasses to examine every detail closely.?

Preparing Metal for Engraving

Engraving on metal jewelry is a beautiful way to make a piece of jewelry unique and memorable. It’s also a great way to personalize a gift for someone special in your life. However, engraving on metal can be difficult, as certain materials require different preparation methods in order to achieve the best results. This article provides an overview of how you can prepare metal for engraving so that you have the perfect surface to work with.

The first step in preparing metal for engraving is to ensure that it is clean and free of any dirt or debris. Using a fine brush, softly scrub away any grime from the surface of the jewelry until it appears sleek and shiny. Alternatively, you can use a soft cloth moistened with a mild soap to wipe down the item prior to engraving.

Once it has been thoroughly cleaned, use sandpaper or steel wool to lightly scuff the metal so that grooves and marks are visible on its surface. Doing this allows for more detail in your engravement design and ensures better transferability when transferring your design onto the metal object.

Another important factor when preparing metal for engraving is avoiding potential pitfalls that could put your project at risk such as elemental migration between components and scratches caused by improper handling techniques during cleaning or scuffing processes mentioned earlier. To help minimize these risks, always wash your hands carefully before handling the jewelry being engraved as oils from even clean hands can cause issues with elemental migration once heated up during etching process.

Additionally, ensure proper protection such as goggles when dealing with certain substances related to laser etching – such as potentially hazardous gases released when etching metals like zinc or nickel alloys – so as not to put yourself at risk of harm due too inadequate safety precautions taken during work environment setup phase.

Finally, if doing laser etching keep in mind factors like geometry complexity which might increase time required do finish given task due to increased number of layers needed in order get desired look and detailed groove structure wanted – this will make sure project takes less time overall because proper preparation leads to better result.

Furthermore ensure headlamp used actually corresponds with type energy output needed based off material size/depth requirements beforehand – else there might be issues stemming from type power settings chosen meaning further complications down road would arise (e.g., overheating).

All these tips should help create an optimal canvas on which you can perform your intricate masterpiece using just one tool: your skillful knife hand. While mistakes may still happen along journey – especially while learning – just remember that practice will enable more confident execution next time around so don’t give up hope even first attempt seems unsuccessful.

Designing a Metal Engraving

Choose your Font or Artwork

An important first step for any engraving project is to decide on the right font or artwork. Commonly used fonts and artworks for engraving include fonts such as Arial, Verdana, Impact and Helvetica, as well as script and decorative typefaces like French Script, Bickham Script and Harlow Solid Italic. Additionally, you may also choose to have a unique design commissioned from an artist for your engraving project.

If you have artwork ready you can easily vectorise it using a program like Photoshop and CorelDraw. Whatever kind of artwork you use, ensure that the design can be easily read when engraved on metal jewelry of your choice.

Get Ready to Engrave

The next step is deciding which metal alloy and size of jewelry will look great with the engraving in order to select the right equipment for the job. It’s usually best to use jewelry made out of medium-density metal alloys (such as gold fill, sterling silver) because these are easy to work with while engraving delicate details into smaller pieces of jewelry.

For high-detail work, you should opt for hand tools such as an engraver pen instead of an electronic rotary tool due to its precision.

Selecting Your Jewelry Piece

Once you have settled on an appropriate tool, it’s time to select your metal jewelry piece. To ensure quality results, make sure that all surfaces are clean before starting any works – remove oils or dirt from surfaces by using a towel dipped in water mixed with dish soap before beginning your work.

Reputation of the supplier is another important factor – make sure that they use premium alloys in their collection so that even after many years go by, your engraved piece won’t wear off too easily. Finally, pay attention not only to how words will appear when rearranged but also keep in mind minor imperfections such as texture differences between letters – this ensures that even small details stand out when seen up close.

Engraving Process

Engraving metal jewelry is an art form that has been around for centuries. It can range from simple and stylish designs to elaborate and intricate pieces of artwork. Engraving can be used with all kinds of metals, both hollow and solid, including platinum, silver, palladium, copper, brass, and nickel.

Every metal responds differently to the etching process so it’s important to understand the nuances of each before beginning your project. To get started with engraving, follow these steps for success.

First set up the work area with a vice or holder strong enough to keep the jewelry piece steady as you work. It is also recommended that you wear protective glasses and gloves in order to protect yourself from any sharp objects or debris kicked up while engraving.

Adjust a rotary tool such as a Dremel or practice grinder to a lower speed setting and choose the correct bit size according to specifications. Carefully place the metal jewelry into the the vice or holder so that it is secure and unable to move freely while working on it.

Start by lightly Etching away at the surface creating thinner lines than if carving deeper into metal forms much easier when using multiple passes throughout areas where desired lettering will eventually appear. Use light pressure on top of added lubrication such as WD-40 lubricant or mineral oil The next step in engraving is adding depth and detail through rapid scratching while holding onto one side at all times for stability.

Use an “up-down” motion across areas where desired text will be etched onto surface of piece in repetitive light strokes This requires some practice to attain finesse but also allows user more control over engagement force depending on design preference or type of material being worked on.

Finally use some medium grade sandpaper with temperatures reaching 300 degrees Fahrenheit depending on settings being utilized during this phase This method will not create overly bold lines but rather soften edges resulting in a more polished look which suits many engraved pieces better than harsh contrasts produced other types material removal techniques such chiseling out letters manually using drill bits etcetera.

Finishing Touches

Sanding and Polishing

After engraving is complete, the metal needs to be sanded and polished to achieve a professional look. If the metal is made of gold, silver, brass, copper or any other precious metal then it should be cleaned with mild detergent and brush before air drying. Then use 500 grit sand paper to gently sand the metal in-order to remove any scratches and burrs created by the engraving process.

To finish off the look, you can apply a jewelry polishing compound or buffing wheel for a high shine. For most metals you can also bring out a natural patina using an electric buffer or muslin buffing wheel and black rouge polish.

Choosing Your Magnification

The type of magnification used for engraving will depend on your project requirements. If you are looking for fine detail work then it’s recommended to use higher magnification power such as 10x or 30x. However if you are just doing basic ornamentation or lettering then lower magnifications of 3x-7x will suffice.

Make sure that you select quality optics so that your jewels maintain maximum clarity during the engraving process especially if intricate details are required. Note that utilizing higher magnification lenses may increase your precision but also adds more time to the overall process.

Patterns, Textures & Color

Engraved jewelry allows room for creativity and features ornamental designs such as stone settings or filigree work that are not able to be achieved with traditional methods. Furthermore gemcutters may carve clear stones into various shapes with patterns sized precisely according to one’s personal taste.

Other techniques involving textures can be used on many metals such as piercing, plating and enameling which enables endless options when personalizing jewelry pieces. Colors applied directly onto metals through anodization enhance aesthetics dramatically bringing vibrancy extending beyond simple engravings producing more dynamic results which last in addition to making maintenance easier in comparison with paint materials (generally).

Maintaining Engraved Metal Jewelry

In order to ensure that your engraved metal jewelry remains beautiful and intact, it is essential to take proper care of the item. After engraving, store metal jewelry in an area where nothing else will touch it. This can include a jewelry box, fabric pouch or even a sealed plastic container with no moisture present. Ensuring your item is stored correctly helps prevent scratching or other damage which may ruin the fine detail you have created.

When wearing jewellery while engaging in activities such as swimming, it is important to ensure any engraving present is covered up. Chlorine and salt water can lower the sharpness of the engraved lettering on metal jewelry, which means that you should place something else in between your accessory and your skin when entering a body of water. This could be as simple as placing a piece of cloth over the engravings so they are not exposed directly to any liquid.

Along with taking care when exposing your engraved metal jewelry to liquids or other objects that may scratch it, you must also regularly clean your items if they come into contact with lotions, oils or perfumes – these can all contribute to wear down the finesse of the engraving over time.

To counteract this problem, it’s best practice to give your jewelry a wipe down every now and again using soapy water and soft rag and then immediately dry using a chamois cloth or paper towel before storing away safely when not being worn.

Following all these steps will help ensure all your engraved metal jewelry stays clean, sparkly and beautiful for many years to come.

Conclusion

Engraving on metal jewelry is a great way to personalize or commemorate any piece of jewelry. With a few basic materials and tools, your design and text can quickly come to life. The results can be quite impressive and the process is surprisingly straightforward.

To get started, you will need some engraving tools, such as a burin or graver in different sizes; protective eyewear; a range of grades of abrasive papers for creating the desired depth or texture; and mild steel balls for buffing away corrosion and imperfections. It may also be beneficial to have on hand some white paint pens, which are ideal for shading in small areas of the design that require more precision than is possible with fine sandpaper.

You may also want to have some porcelain dishes available for placing abrasive compound when wet engraving.

To begin the actual engraving process, first mark out the area you wish to work with using an awl or scribe tool – depending on the hardness of the metal used different strokes will render different depths and patterns into the material.

Once this is done you can use either wet engraving with an electrically charged needle, or dry engraving with a burin – both processes must be undertaken carefully as there is an actual physical alteration to the metal that cannot be undone.

Depending on what look you are after, you can choose between manual and machine engravings; each will achieve different results though they do require different levels of experienced skill-sets for success.

Finally, when your work is complete it’s important to protect it from developing corrosion by using specific plating solutions and clear lacquers if desired. Take care when working at each step, as even a slightly off measurement could cause uneven lines or disturbatic detailing in your piece’s overall aesthetic appeal.

And if needed, refer to various tutorials online or find someone experienced with these techniques so that you have added confidence in accomplishing your desired engraved designs with ease.

Welcome to my jewelry blog! My name is Sarah and I am the owner of this blog.

I love making jewelry and sharing my creations with others.

So whether you’re someone who loves wearing jewelry yourself or simply enjoys learning about it, be sure to check out my blog for insightful posts on everything related to this exciting topic!