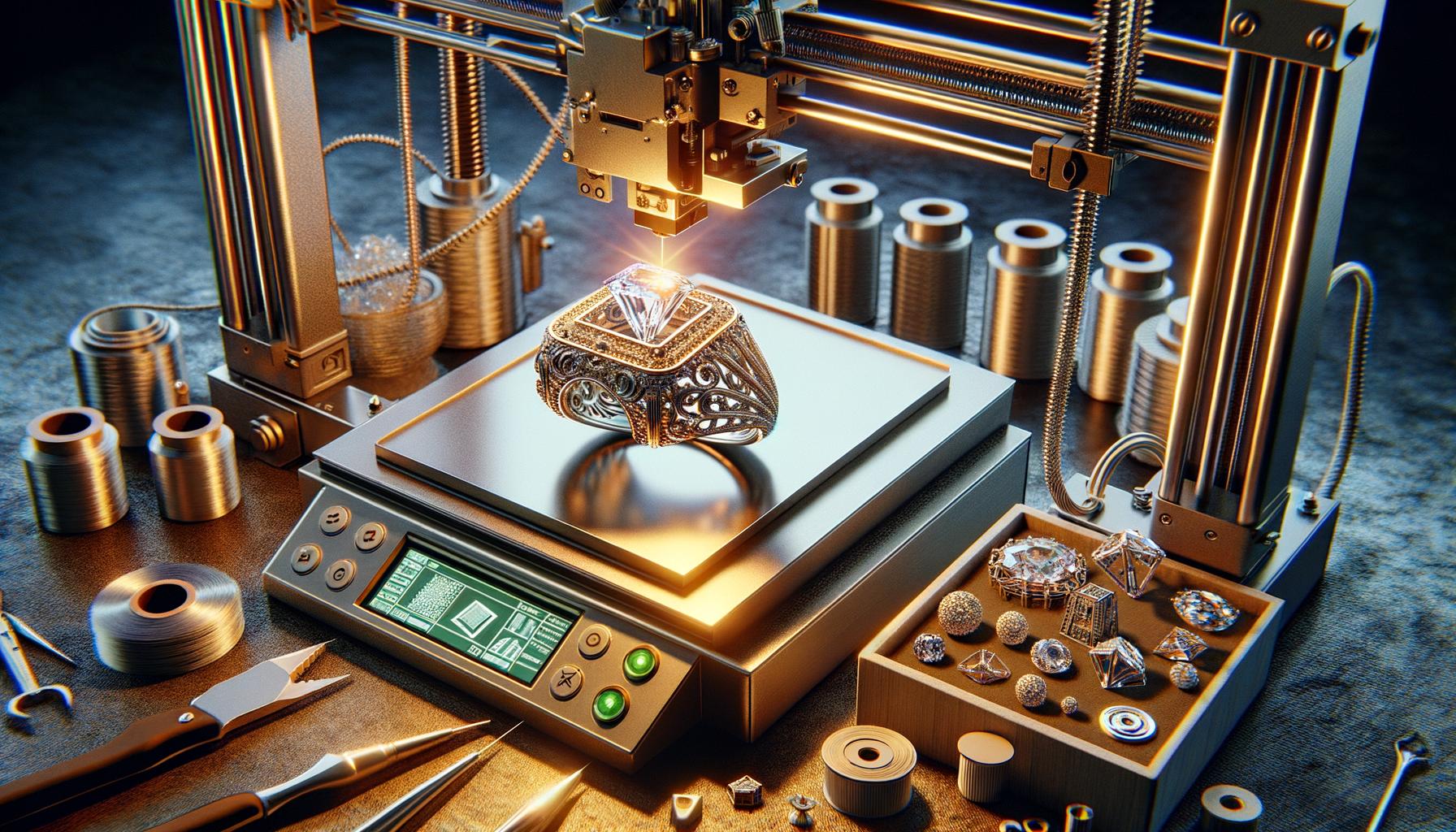

How 3D Printing Is Changing the Role of the Jewelry Designer

Jewelry design has long been an art form rooted in tradition, where skilled artisans painstakingly craft intricate pieces through labor-intensive processes. Historically, the journey from concept to adornment involved a series of meticulous steps, carefully orchestrated by master craftsmen who …