Metal clay is a material that has revolutionised the world of jewellery making. As its name implies, metal clay is made up of tiny particles of metal blended with an organic binder and water, producing a clay-like material which can be worked with in much the same way as traditional modelling clays. This makes it an ideal tool for creating intricate designs and shapes, as well as engraving patterns or inscriptions into surfaces.

The strength and durability of the final product means it’s often used to make wearable items of jewellery. But can you use metal clay to repair jewelry? What other uses does it have when it comes to creating and customising pieces?

Making Repairs With Metal Clay

Metal clay is perfect for repairing costume jewelry which is typically made from less durable metals such as brass or nickel plate. Since metal clay consists of fine particles, it can be moulded into any shape or size needed to fit back broken pieces or fill cavities caused by wear and tear.

Once three components are mixed together correctly – the metal powder, binder and water component – the mixture will harden at room temperature after 2 hours; this time may vary depending on ambient humidity levels so its best to keep track at all times.

It can then be sanded and polished just like any other metal object, allowing a range of options for people wanting to customise their own pieces. There’s no need for soldering either, saving you valuable time which would otherwise be spent finding solder and preparing a suitable area to work in.

Embellishing Existing Jewellery Items

Metal clay also offers creative freedom when creating embellishments or designs onto existing pieces of jewelry. Most metals used in jewellery making are compatible with metal clays so you are free to incorporate beads, wires, filigrees or even larger shapes without worrying about damaging your own piece or having to consult an experienced jeweller beforehand.

In addition, Metal Clay can easily adhere onto other surface areas if required giving you even more possibilities when designing new looks for old pieces that may be gathering dust deep in your collection box.

The Benefits of Metal Clay for Jewelry Repair

Metal clay is a great way to repair jewelry in addition to creating new and unique pieces. Metal clay is composed of tiny particles of metal and organic binder, allowing it to be shaped into almost any form with hand tools.

Because of this, the material can be used to repair broken jewelry components that would otherwise require welding or soldering. Jewelers appreciate metal clay because it does not require expensive equipment or specialized skills that can take time to learn.

Using metal clay for jewelry repairs provides some distinct benefits when compared to traditional methods like welding and soldering. Since metal clay can be molded by hand, it is much easier to follow the contours of existing jewelry designs without needing heat, electricity or combustible chemicals – saving time and reducing costs for skilled labor.

Moreover, working with metal clay often allows for more delicate repairs as well as adding features like texture or custom accents that can further personalize the piece. This makes it easier for jewelers to replicate complex elements that may have been difficult or impossible when working with traditional methods of repair.

In addition to being easier and quicker than other methods, metal clay also often uses less metals in its construction which makes repairs more affordable than they might otherwise be. This is because the tiny particles of metal contained in the clay mix allow jewelers to create smaller parts and pieces in intricate detail which reduces waste and yields a higher cost-efficiency overall – making it both cost effective as well as appealing aesthetically.

Plus, the end result does not have any visible seams so small repairs can look just as natural as larger ones using conventional techniques. Ultimately, using metal clay for jewelry repairs offers an easy and stylish way for artists to extend the life of beloved items without compromising its design – providing both a practical solution and artistic satisfaction in one go.

What Jewelry Repairs Can Metal Clay Be Used For?

Metal clay can be used to make many types of jewelry repairs. As the name implies, metal clay is made up of a combination of metals that have been finely ground or blended together. It can be formed into just about any shape, making it an ideal material for repairs ranging from replacing a missing chain link to creating a new setting or shank for a ring.

Metal clay can also be used to fill in cracks in existing jewelry or enamel pieces so they look like new again. Depending on the type of repair and skill level needed, metal clay can provide both aesthetic and structural benefits to restore a piece of jewelry.

In addition to being able to mold the material into almost any form, metal clay is sold in different types with various ratios of metals so you get the best possible result for your jewelry repair goals. For example, silver clays contain mostly silver and only trace amounts of other elements such as copper and nickel which is why they are much more expensive than bronze or iron clays which contain significant amounts of non-precious metals and alloys.

Metal clay also comes in varying degrees of hardness so you can use it for intricate detailing or thicker structures that offer more durability if you need something stronger.

Finally, metal clays aren’t just limited to repairing broken jewelry components – they can also be used to give existing jewelry designs a custom touch. For example, you can use metal clays to add texture and decorative details such as cabochons and decorative stones, textures and even metal filigree work that creates an artisan look as part of your design.

You can mix metals with different colors too – enabling you to combine copper and sterling silver – adding even more interest to your designs. Metal clay is an incredibly versatile material that enables artisans and jewelers alike to transform existing pieces or create totally unique designs from scratch without spending lots of money acquiring rare materials or tools.

Preparing for Jewelry Repair Using Metal Clay

When you want to repair a piece of jewelry with metal clay, the first step is to prepare for the task. This starts with gathering all the necessary supplies. You will need metal clay, either silver or gold, as well as a rolling pin, slab roller, a small water bottle and brush for cleaning up after working.

You may also need some stringers or thin strands of the same metal in order to fill in any gaps in the repair. If you are repairing a bezel setting, you may require some adhesive ball tips and other special tools depending on the complexity of the repair job (e.g., prongs). Once all this is gathered together, it is time to get down to work.

Creating The New Jewelry

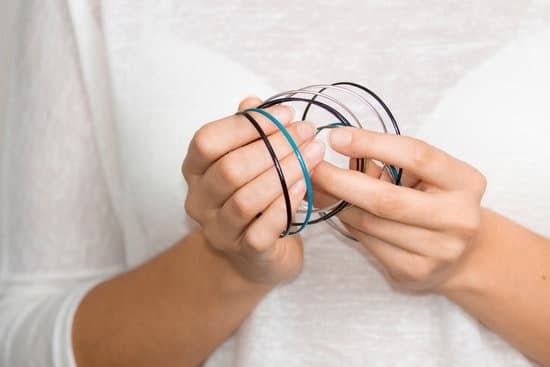

Next comes creating your new piece of jewelry using metal clay. Start by making sure that you have enough material so that when it dries and shrinks it will still fit into place over the existing bezel or parts of your jewelry that need repair. Roll out a slab of the clay and cut out any pieces that need replacing from this slab.

Assemble these parts back together as needed and then use shape tools ora needle tool if desired to make sure everything fits perfectly together before leaving them aside for drying/firing. Some firings may require more than one firing to ensure certain pieces hold their form better during those firings at higher temperatures.

Firing The Metal Clay

Roughly thirty minutes is usually enough time for most standard clays to dry but different firms may have diifferent recommended times based on theirclay type – check with your provider if unsure about this aspect – before carefully packing them into your kiln or leaving them out in direct sunlight depending on your preferred method of curing and firing metal clays.

A kiln can reach temperatures up to 1900F while direct sunlight won’t be any hotter than around 180F which isn’t hot enough for sintering silver but works fine for silver-plated pewter clays or Bronzclay fires which only require temperatures around 1000F – 1300F respectively.

Make sure not to overheat any metals during this process since excessive heat has damaging effects on jewelry pieces.

Step-By-Step Instructions for Working with Metal Clay

Metal clay is an amazing material that can be used to create unique pieces of jewelry. It’s also incredibly versatile, allowing you to craft intricate designs and repair damaged jewelry. If you’re dealing with a broken necklace, ring, or other piece of jewelry and are wondering if metal clay can help fix it, the answer is: yes.

However, it does require precision and practice to ensure a secure repair. With these step-by-step instructions on repairing jewelry with metal clay, you’ll be able to give your precious items some much-needed TLC.

Before getting started, make sure you have all of the necessary supplies on hand for the job. You’ll need some metal clay (of course), as well as a few tools like sculpting tools or needles in various sizes for working small details in the metal clay itself. You’ll also need wax paper to keep things clean and rubbing alcohol for cleaning up any fingerprints left behind from the process.

Next comes the prep work: thoroughly clean both surfaces that need to be mended – this includes polishing any old solder remnants off of the original piece. Make sure to wear protective glasses when doing this so no particles get into your eyes accidentally.

After that has been completed, use your tools to shape new metal clay sections into any rough repair pieces needed, such as rounded beads or extensions for missing components in the original design of the piece. Once your repair pieces are made, set them aside until they’re ready to be added onto your project.

Now take all those newly created pieces and start attaching them using metal paste – but carefully. Try not to touch too much of the fresh paste with your fingers since it will quickly oxidize and become less malleable or even discolor due to contact with oxygen or water vapor in the air (like sweat).

This may cause problems when trying to adhere all parts together in one unified shape later on down the line. When complete, let it dry overnight before handling at all; otherwise it could ruin your hard work.

Tips and Tricks for Jewelry Repair Using Metal Clay

The thought of jewelry repair can be intimidating for many craftspeople and jewelers, but with the invention of metal clay, it has become an easier process. Metal clay is a formable material that can easily be manipulated like a clay before hardening and turning into metal when fired. It is composed of particles of processed metals like golds and silver that are suspended in an organic binder so that the clay can be formed with normal hand tools.

When fired, the piece becomes solid metallic form and ready for polishing or filing. This makes metal clay an ideal choice for jewelry repair as it can be used to fix even complex or detailed designs with ease.

When choosing metal clay for jewelry repair, choose one specifically designed to fuse and adhere to existing metal components such as jump rings or pendants. As metal clays have different metals which vary in their malleability, strength and fire temperature, ensure you use a compatible one which won’t react adversely with your existing jewelry materials during firing.

Use pieces cut from rolled sheets or paste forms when making joins between existing parts rather than attempting to smush together entire pieces of wet clay; this will create stronger bonds able to withstand wear and tear over time.

It is often more efficient to start off by developing your design on paper before starting work on actual jewelry repairs using metal clay. This allows you identify mistakes beforehand where possible instead of after having committed resources such as precious metals onto parts that may not fit together as expected later down the line.

Preparation is key when looking to successfully apply metal clay in jewelry repair projects, so dedicate enough time to plan ahead while taking note of all parameters likely to impact your design’s outcome at each stage of its production progression – there is always room for improvement.

Finishing and Caring for Metal Clay Repaired Jewelry

Metal clay is a unique material made from microscopic particles of silver, bronze, or copper, combined with an organic binder and water. This combination makes metal clay very malleable and easy to work with. It can be molded into any shape or form needed and fired in an oven or kiln until the desired hardness is achieved.

Metal clay can easily be used to repair jewelry as it can be shaped and formed just like any other metal. Once it has been fired, it will have all the properties of the metal it was made from.

One advantage of using metal clay over more traditional metals for repairing jewelry is that a greater level of detail and finesse can be achieved much more quickly than with regular metals. Metal clay also requires less specialized tools than many other metals making it an ideal choice for home repairs. With just a few basic tools such as rolling pins, dice, stamps, or needles you can create intricate designs and make detailed repairs to your jewelry right at home.

Once you have formed your repairs out of metal clay you will need to finish them off in order for them to look their best. To accomplish this you will first need to sand down the repaired areas to sculpt away imperfections and remove any residual dirt or dust that may have been left behind during the forming process.

After this, you should use a polishing wheel to get rid of any scratches that may still remain before buffing out your newly repaired jewelry item until it shines brightly like new again. Finally, apply some protective wax or coatings so that your hard work does not ruin itself when exposed to elements such as air or moisture over time.

Summary and Conclusion of Using Metal Clay for Jewelry Repair

Metal clay has become increasingly popular in recent years as a material to use for repairing and creating jewelry. Its versatile nature allows it to be used for any type of object, from small charms to full pieces of jewelry. It’s incredibly easy to work with and requires very little specialized equipment or materials, making it an ideal choice for both amateur and professional jewelers.

One of the greatest advantages of metal clay is that it can easily be used for intricate repairs on existing pieces of jewelry. Whether you’re missing a few gems or a whole piece, metal clay can help restore the original look and feel.

You can shape and form the metal clay into whatever shape you need for the repair and then press it into the area where the original piece was located. With some additional finishing techniques, such as polishing or burnishing, you can make your repair look almost indistinguishable from an original piece.

When using metal clay to repair jewelry, it is important to take your time during each step of the process. It takes patience and precision to ensure that all your pieces come out perfect each time.

Once your work is complete, you should consider coating your finished product with a special lacquer or sealant in order to protect its quality over time. With proper care and maintenance, you can get many years of use out of a jewellery piece repaired with metal clay.

Welcome to my jewelry blog! My name is Sarah and I am the owner of this blog.

I love making jewelry and sharing my creations with others.

So whether you’re someone who loves wearing jewelry yourself or simply enjoys learning about it, be sure to check out my blog for insightful posts on everything related to this exciting topic!