Jewelry making is an intricate and rewarding art that allows for the creation of personal, meaningful pieces. For those looking to enhance their craft or explore new techniques, understanding how to use molds in jewelry making: tips and tricks can significantly expand your capabilities. Molds serve as invaluable tools, enabling artists to replicate detailed designs with consistency and precision.

Using molds in jewelry creation offers multiple benefits. Not only do they save time by providing a pre-formed shape for your materials, but they also allow for the repetition of complex designs without compromising on detail. Whether you’re working with resin, clay, or metal, molds can simplify the process and ensure a professional finish. They are particularly useful when crafting intricate patterns or trying to produce multiples of the same piece.

This blog post aims to provide readers with comprehensive insights into utilizing molds in their jewelry-making projects. From choosing the right type of mold and gathering necessary tools to step-by-step instructions for creating beautiful pieces, you’ll find everything you need to get started. Additionally, we’ll share expert tips and common pitfalls to avoid, ensuring that your journey into mold-based jewelry making is both enjoyable and successful.

Types of Molds Used in Jewelry Making

Silicone molds are a popular choice among jewelry makers due to their flexibility and ease of use. These molds can be found in various shapes and sizes, making them perfect for crafting intricate designs without requiring excessive effort or skill. The primary advantage of silicone molds is their non-stick nature, which ensures that cured materials like resin can be easily removed from the mold without damage.

Silicone molds are durable and reusable, offering excellent value over time. They work well with different materials such as resins, clays, and waxes.

Metal molds, in contrast, provide superior durability but require more care during both the creation and removal processes. Known for yielding high-quality pieces with sharp details, metal molds are ideal for projects requiring stringent detail and long-term use.

One effective tip when using metal molds is to ensure they are properly prepped with release agents to avoid sticking issues. Release agents create a barrier between the mold surface and your material, simplifying the demolding process and preserving the integrity of your project.

Flexible plastic molds offer a middle ground between silicone and metal options. These molds are generally less expensive than silicone ones but may not last as long unless meticulously cared for. Their pliability allows easy release of cured resin or clay items; however, care must be taken to avoid distorting delicate designs during removal. Flexible plastic molds are suitable for beginners looking to practice basic techniques before investing in more durable options like silicone or custom-made metal molds.

| Mold Type | Advantages | Common Uses |

|---|---|---|

| Silicone Molds | Non-stick, flexible, reusable | Resin jewelry pieces with delicate details |

| Metal Molds | Durable, high-quality output | Projects requiring sharp detail and longevity |

| Flexible Plastic Molds | Pliable, less expensive | Beginner practice projects, experiments with shapes |

When it comes to custom molds, there are specific scenarios where going custom is highly advantageous. Custom molds allow artists to bring unique design visions to life that pre-made options cannot support.

Whether it’s casting family heirlooms into new jewelry or creating brand-specific pieces for sale, custom molds elevate one’s creative potential significantly. Understanding how to use these different types efficiently adds depth to your knowledge of how to use molds in jewelry making: tips and tricks that can enhance your overall craftsmanship quality.

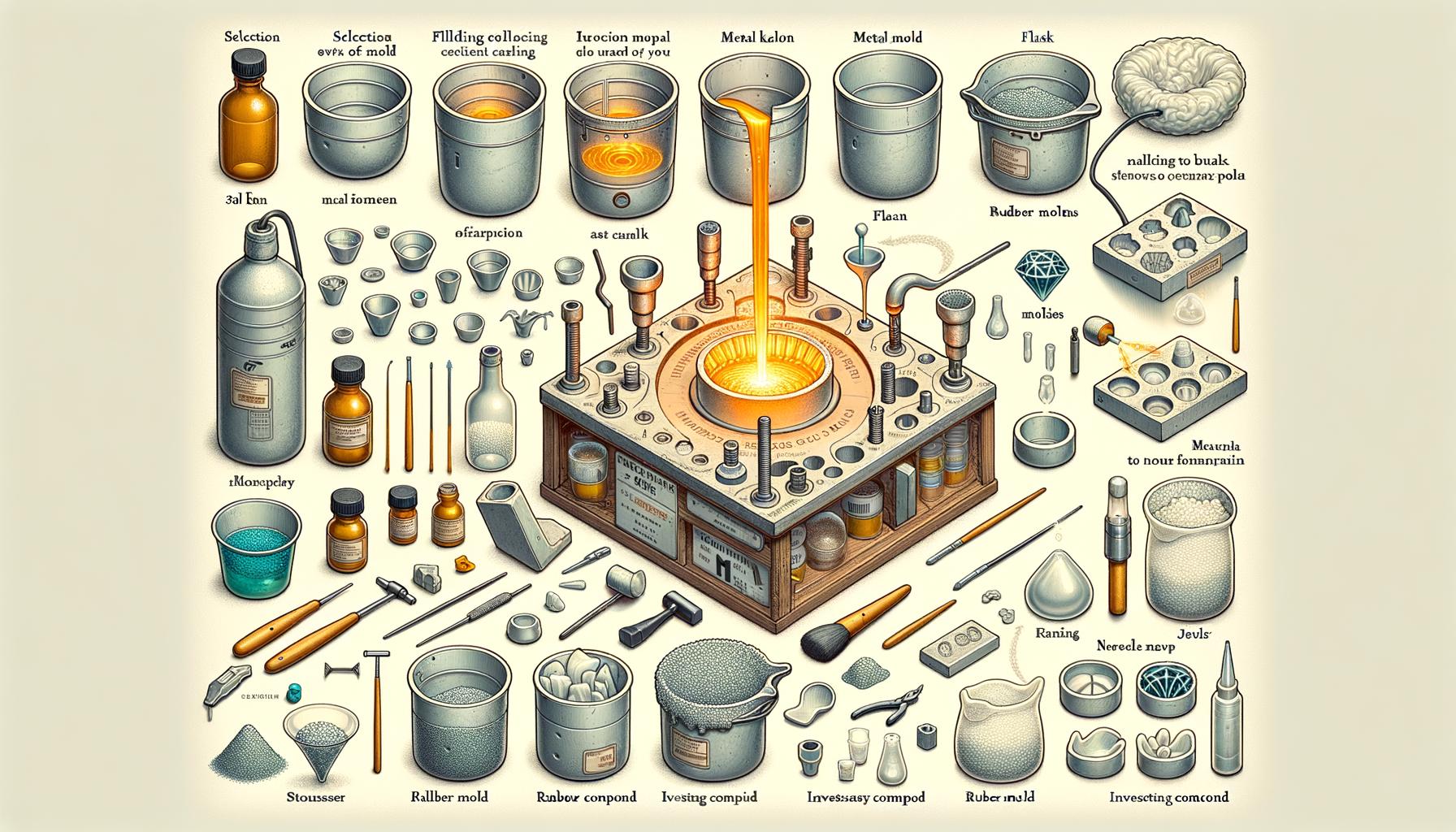

Essential Tools and Materials

Working with molds to create jewelry requires a variety of essential tools and materials. Your basic kit should include a selection of molds, resin or clay as your primary materials, and release agents to ensure smooth removal of finished pieces from the molds.

Silicone molds are particularly popular due to their flexibility and ease of use. When learning how to use molds in jewelry making: tips and tricks can be invaluable as they help you select the right type for your project.

Specialized tools that facilitate mold jewelry making include fine detailing brushes, mixing cups, spatulas, and precision weighing scales. These tools help in mixing materials with additives like pigments or glitter for unique designs. Safety gear is also indispensable when working with resins and other chemicals; gloves protect your skin from direct contact with potentially harmful substances, while masks ensure you don’t inhale fumes.

Maintaining an organized setup prolongs the life of your tools and makes it easier to find what you need during different stages of your project. Make sure to allocate space for each category of items – store all similar tools together and label their compartments if possible for quick access.

| Tool/Material | Purpose |

|---|---|

| Mixing Cups | Combining resin or clay with additives |

| Fine Detailing Brushes | Adding intricate details or touch-ups |

| Gloves & Masks | Protective gear against harmful chemicals and fumes |

Preparing Your Workstation

Setting up an efficient and safe workstation is crucial for successful jewelry making, especially when working with molds. The first step in preparing your workspace is to ensure you have ample room to spread out your tools and materials.

A large, flat surface is ideal as it offers plenty of space for different stages of the molding process. You should also have a designated area specifically for mixing and pouring materials like resin or clay to keep everything organized and minimize the risk of spills.

Safety precautions are paramount in any crafting environment. Ventilation is one of the most critical factors since many materials used in jewelry molding can emit harmful fumes. Make sure that your workspace has adequate airflow-this could be an open window, a fan, or ideally, both.

Additionally, always wear protective gear such as gloves and safety glasses to protect yourself from potential splashes and spills. If you’re working with resins or other chemicals, consider wearing a respiratory mask to ensure you’re not inhaling toxic fumes.

Organizing your tools and materials ensures that your workflow remains smooth and uninterrupted. Here are some useful tips for keeping everything within easy reach:

- Tool Caddy: Use a tool caddy or dedicated storage containers to keep smaller items like paintbrushes, tweezers, and cutting tools sorted.

- Labeling: Clearly label all containers and compartments wherein you’ve stored different supplies, so you can easily locate what you need.

- Clean Workspace: Keep cleaning wipes or a small vacuum cleaner nearby to quickly address any spills or debris.

Having an orderly setup enhances not only efficiency but also the overall enjoyment of the craft. Knowing how to use molds in jewelry making: tips and tricks becomes much more straightforward when you don’t have to fumble around looking for your essentials mid-project. Proper preparation translates into better-crafted jewelry pieces by allowing you to focus fully on creativity without interruption.

Step-by-Step Process

Selecting the Right Mold for Your Project

The first step in mastering how to use molds in jewelry making: tips and tricks is selecting the right mold for your specific project. Various types of molds are available, including silicone, metal, and flexible plastic molds. Silicone molds are generally the most popular due to their flexibility and ease of use.

They allow for a smooth release of both resin and clay pieces with minimal effort. Metal molds, on the other hand, offer great durability but require more effort when demolding. Flexible plastic molds fall somewhere in between; they are affordable but less durable than silicone or metal counterparts.

To select the appropriate mold, consider what type of material you’ll be using-resin, clay, or another medium-and choose a mold that can handle that material efficiently. Additionally, pay attention to the intricacy of your design. More detailed pieces might benefit from high-quality silicone molds that can capture fine details more effectively.

Preparing the Mold for Use

Proper preparation is crucial for achieving professional-looking results when making jewelry with molds. Begin by thoroughly cleaning your mold to remove any dust or debris that could affect the final piece. Silicone molds can normally be washed with warm soapy water and allowed to air dry completely before use.

Next, apply a release agent if necessary. Release agents help ensure that your finished jewelry pieces come out effortlessly without sticking to the mold surfaces. This step is particularly essential when working with more rigid materials like resin or metal clay. Simply spray or brush a thin layer of release agent onto all areas of your chosen mold and let it dry according to manufacturer instructions.

Mixing and Pouring Materials

Once your mold is prepped and ready, it’s time to mix and pour your materials into it. Different materials require different mixing techniques; for example, resin usually involves combining two parts-a resin base and a hardener-in exact proportions as recommended by the manufacturer. Mix thoroughly to avoid any unmixed pockets which can lead to an uneven curing process.

When pouring your mixed material into the mold, take measures to minimize air bubbles which can mar your final product’s appearance. One effective technique involves pouring slowly in a thin stream while gently tapping the sides of the mold to encourage bubbles towards the surface where they can pop easily.

By following these steps closely-selecting an appropriate mold, prepping it properly, and accurately mixing and pouring materials-you’ll set yourself up for success in creating stunning jewelry pieces using molds.

Demolding and Finishing Techniques

Demolding your jewelry pieces can be one of the most exciting moments in your creation process, but it requires careful handling to avoid damaging your hard work. First and foremost, make sure that your piece is completely set or cured before attempting to demold. Incomplete curing can result in warping or tearing of resin-based materials and inadequate setting for clay projects.

For silicone molds, gently flex the mold away from the edges of the piece and gradually work around until the jewelry item releases. Metal molds generally require a slight knock or tap to release their grip.

Once you have successfully removed your pieces from the mold, it’s time to focus on finishing techniques like sanding and polishing. Imperfections such as excess material or rough edges can be addressed using fine-grit sandpaper, emery boards, or even specialized micro-mesh pads.

Sanding should be done in stages, starting with coarser grits to trim away larger defects and finishing with finer grits for a smooth surface. Polishing compounds are useful if you want a high-gloss finish; apply them with a soft cloth or buffing wheel for best results.

Adding finishing touches is where you can let your creativity shine. Whether you’re painting intricate designs on polymer clay earrings or embedding tiny gemstones into resin pendants, these embellishments can elevate your pieces from simple to stunning.

Consider using paint markers specifically designed for adding details without smudging or brush strokes. If you’re working with inclusions like dried flowers or glitter, ensure they are securely embedded during the casting process but also consider adding a thin layer of clear resin over them post-demold to ensure longevity and depth.

| Stage | Techniques |

|---|---|

| Demolding | Gently flex silicone molds; tap metal molds |

| Sanding & Polishing | Use fine-grit sandpaper; apply polishing compounds |

| Finishing Touches | Add paint details; embed gemstones/inclusions |

Understanding how to use molds in jewelry making: tips and tricks involves mastering these finishing techniques to achieve professional-looking results every time. With practice, you’ll gain confidence in transforming raw creations into beautifully polished works of art ready for wear or sale.

Creative Tips and Tricks for Mold Jewelry Making

How to Add Inclusions

One of the most exciting aspects of learning how to use molds in jewelry making: tips and tricks is discovering the art of adding inclusions. Inclusions such as glitter, dried flowers, or pigments can elevate a simple piece of jewelry into something unique and stunning.

When incorporating glitter, it is best to mix it directly with your resin or clay before pouring it into the mold. However, be mindful of the amount used; too much glitter can overwhelm your piece and may interfere with curing.

For natural elements like dried flowers, ensure they are completely dry to avoid moisture-related issues later on. Arrange them carefully within the mold before pouring your base material. Pigments offer an excellent way to add vibrant color to your creations; mix them thoroughly into your resin or clay to ensure even distribution. If you’re aiming for a more nuanced effect, consider adding pigments in layers to create depth and interest within your piece.

Layering Techniques

Mastering layering techniques will allow you to create multi-dimensional pieces that captivate the eye. This technique involves allowing one layer of material-such as resin-to partially cure before adding another layer. By doing so, you can embed objects like small charms or even additional colors between layers without them blending together undesirably.

To achieve a polished look with layering techniques, patience is key. Allow each layer adequate time to cure according to the manufacturer’s instructions but be vigilant not to let it cure entirely if embedding objects between layers; this ensures good adhesion between subsequent pours. Experimenting with transparent and opaque layers can produce dramatic effects, creating visual depth that changes based on light angles.

Mixing Colors and Achieving Desired Effects

When mixing colors for mold-based jewelry projects, understanding color theory basics can significantly impact your outcomes. Combining primary colors (red, blue, yellow) in various quantities will yield secondary colors (green, purple, orange), which you can then further mix for tertiary shades. Using high-quality pigments that are compatible with your base materials ensures vibrant results.

Another useful tip is using a toothpick or skewer stick after pouring colored resins into the mold-gently swirling these tools through different hues creates marbled effects that add sophistication and intrigue. Metallic powders can also introduce shimmer and shine when mixed cautiously with resins or clays; uneven dispersion leads to alluring striations mimicking precious stones’ appearances.

Whether you are a novice or an experienced artisan exploring advanced techniques in mold jewelry making requires dedication but brings immense satisfaction when done correctly.

Common Mistakes and How to Avoid Them

When diving into the world of mold jewelry making, you may encounter a range of common mistakes that can hinder your progress. One frequent pitfall is dealing with air bubbles in your resin or clay pieces. Air bubbles can ruin the aesthetic and structural integrity of your jewelry. To minimize bubbles, always mix materials slowly and pour them gradually into the mold. Additionally, lightly tapping or vibrating the mold immediately after pouring can help to release trapped air.

Another common issue is incomplete curing, which can result in soft or sticky pieces that lack durability. Incomplete curing often arises from incorrect mixing ratios or insufficient curing times. Make sure to follow the manufacturer’s instructions meticulously when working with resins and clays, paying attention to recommended mixing ratios, ambient temperature conditions, and curing durations. Investing in a quality timer can be beneficial to ensure you adhere strictly to these guidelines.

Sticking to molds is another frustration many beginners face while learning how to use molds in jewelry making: tips and tricks recommend using a reliable release agent before pouring your material into the mold. Sticking issues are often caused by an under-application of release agents or choosing a material that isn’t compatible with the mold type.

Always clean your molds thoroughly and apply an even layer of release agent to avoid this problem. If sticking persists, consider exploring alternative mold materials or different types of release agents designed specifically for your chosen medium.

Ensuring proper organization also plays a crucial role in avoiding many mistakes during jewelry making with molds:

- Keep all tools within reach but well-organized.

- Label containers for easier identification.

- Regularly check inventory levels for essential supplies like mixing cups, stir sticks, and release agents.

Lastly, once you achieve consistency in creating beautiful pieces without these common setbacks, you’ll appreciate more advanced techniques better as each successful piece builds skill-enhancing confidence.

Advanced Techniques and Projects

Taking your jewelry making skills to the next level involves diving into advanced techniques and projects that push the boundaries of your creativity. One challenging yet rewarding aspect is creating custom molds. Start by exploring various materials such as silicone putty or liquid silicone rubber for designing molds that tailor specifically to your vision.

Custom molds allow you to craft unique shapes and intricate details that standard, pre-made molds cannot offer. For those looking to venture further, consider hybridizing materials like resin with metal or incorporating other mixed media elements in your designs. The possibilities are endless, providing an excellent opportunity to experiment and innovate.

Mixed media projects are another exciting avenue for advanced jewelry makers. You can combine traditional mold-making materials with unconventional ones like fabric, wood, or even unconventional objects like nuts and bolts to create truly one-of-a-kind pieces.

Layering different media adds a multidimensional aspect to your work and opens doors for texture play, which can significantly enrich the final product’s aesthetic appeal. Additionally, experimenting with pigments and dyes within these new mediums can yield stunning visual effects that will set your pieces apart.

For those interested in scaling their work up, learning how to use molds in jewelry making: tips and tricks become exceptionally useful when transitioning from smaller items like rings or pendants to larger sets or statement pieces. Consider embarking on projects that involve creating matching sets comprising earrings, necklaces, bracelets, and even decorative accessories like brooches.

This not only enhances your skill set but also allows you to explore consistency in design across multiple formats. Advanced jewelers often use these opportunities to incorporate intricate detailing techniques such as hand-painting embellishments after demolding or embedding complex inclusions during the molding process itself.

Care and Maintenance of Molds

Proper care and maintenance of your molds are crucial for ensuring they remain in good condition and provide consistent results over time. The first step in preserving the longevity of your molds is to clean them thoroughly after each use. For silicone molds, you can wash them with warm, soapy water using a soft sponge or cloth.

Avoid using abrasive cleaners or scrubbers as they can damage the delicate surface of the mold. Metal molds may require more rigorous cleaning methods depending on what material you’ve used them with, but generally, warm soapy water followed by thorough drying should suffice.

An essential aspect of maintaining your molds is proper storage. Store your molds in a cool, dry place away from direct sunlight to prevent any damage caused by UV rays or heat exposure.

Placing them flat and not stacked upon one another helps avoid deformities. If you’re dealing with multiple small molds, keep them organized in labeled containers or zip-lock bags to prevent mix-ups and make it easier to find the specific mold you need for a project.

Taking preventative measures also extends the life of your molds significantly. For instance, always apply a suitable release agent before pouring resin or clay into the mold; this not only makes demolding easier but also minimizes wear and tear on the mold’s surface.

Similarly, avoid over-filling as excess material can spill over and stick to areas outside the intended cavity, causing difficulty in cleanup and potential mold damage. By following these tips on how to use molds in jewelry making: tips and tricks along with diligent care routines, you’ll ensure that your tools remain effective for many future projects.

Regular inspection is another key practice; periodically check for signs of wear such as tears or warping especially around edges where stress is highest during demolding processes. Additionally, if you notice an accumulation of residues that don’t come off with simple washing-for example, resin that’s solidified within grooves-you might need to employ more stringent cleaning methods like soaking in a specialized mold cleaner solution designed for stubborn residues.

When minor damages occur like small tears in silicone molds-repair kits specifically made for fixing such issues can be invaluable tools to have at hand to prolong their usability rather than replacing them immediately.

Conclusion

How to Clean and Store Molds Properly

Proper care and maintenance of your molds are crucial to ensure their longevity and performance in jewelry making. After each use, it’s essential to clean the molds thoroughly to remove any residual material that may have been left behind. For silicone molds, a mild soap with warm water is often sufficient to clean out residues without damaging the mold’s surface.

Metal molds can be scrubbed gently using a soft brush to get into the tight crevices, while flexible plastic molds typically require just a gentle wash. Always make sure the molds are completely dry before storing them to prevent any mold or mildew growth.

When it comes to storage, keep your molds in a cool, dark place, away from direct sunlight or extreme heat which can degrade materials over time. Stack them flat or hang them up if they are flexible enough; avoid throwing them into drawers where they could become misshapen or damaged from heavy items leaning against them. Following these precautions will go a long way in preserving your investment in quality jewelry-making tools.

Prolonging the Life of Your Molds

Understanding how to prolong the life of your molds involves more than just cleaning and storage-it includes proper usage strategies as well. Always apply an appropriate release agent before using your mold; this not only makes demolding easier but also protects the inner surface from scratches and wear over time.

Avoid using sharp tools near or within the mold cavity as these can create gouges and scratches that may affect future projects by causing unwanted texture or even compromising the integrity of the mold.

Another important tip on how to use molds in jewelry making: tips and tricks involve periodically checking for signs of wear such as discoloration, stiffness, or cracking. Address issues promptly by sanding lightly with fine-grit sandpaper if you notice minor imperfections inside silicone or plastic molds. If certain areas seem more worn than others, try rotating parts within versatile designs so that stress is distributed more evenly across different sections of the mold.

When and How to Repair or Replace Worn Molds

No matter how diligently you maintain them, all molds eventually show signs of wear and tear after repeated use. Knowing when it’s time for repair-or replacement-is key in ensuring consistent quality in your creations.

For minor damages like small tears in silicone molds, special adhesive solutions designed for silicone can be used effectively for repairs. For metal molds showing rust spots or tarnishing, consider using rust removers followed by thorough drying and resealing with a protective layer suitable for metal surfaces.

On occasions where damage is extensive-like deep cracks or severe deformities-replacement is often better than attempting repairs that might override functionality down the line. Investing consistently in high-quality new molds ensures your craftsmanship remains top-notch while embracing newer designs opens up fresh creative possibilities.

By adhering closely to these steps for maintaining your jewelry-making essentials, you’re setting yourself up for continued success-and enjoyment-in every piece you create.

Additional Resources

Wrapping up our comprehensive guide on how to use molds in jewelry making: tips and tricks, it’s evident that the world of mold-based jewelry crafting offers a boundless realm of creativity and precision.

From the various types of molds available such as silicone, metal, flexible plastic, and custom-made options, to the essential tools and safety precautions necessary for an efficient workstation-the foundation laid in these sections ensures that both novice and experienced crafters can embark on their projects with confidence and finesse.

As you venture into the step-by-step process of making jewelry with molds, remember that selecting the right mold is crucial to your project’s success. Preparing your mold by cleaning it thoroughly and applying release agents will pave the way for smooth demolding later on.

Equally important is mastering techniques to minimize air bubbles and imperfections during mixing and pouring materials like resin or clay. The guidance provided will help you achieve a professional finish with polished edges and stunning embellishments such as glitter or dried flowers.

Finally, don’t let common mistakes dissuade you from experimenting further. Understanding how to troubleshoot issues like incomplete curing or bubble formation will make each project a learning experience. With advanced techniques like creating custom molds or incorporating mixed media elements, your skills will continually evolve. We encourage readers to share their unique creations and experiences as this journey of learning unfolds-embark boldly on new projects knowing you’ve got a wealth of knowledge at your fingertips.

Frequently Asked Questions

How Do Jewelry Molds Work?

Jewelry molds work by providing a precise negative impression of the desired jewelry piece, allowing for the creation of multiple identical copies. The mold is typically made from durable materials like silicone or rubber that can withstand high temperatures and pressures. First, an original model of the jewelry is created, often out of wax or another soft material.

This model is then encased in the molding material and allowed to harden. After the mold has set, it is cut open carefully to reveal a cavity that perfectly replicates the original design. This cavity can then be filled with molten metal or other casting materials to produce exact duplicates of the original piece.

How Do You Use Casting Molds?

Using casting molds involves a few critical steps to ensure precision and replicate intricate designs accurately. Initially, you must prepare your mold by ensuring it’s clean and free from any debris that could flaw the final product. Once prepared, secure the mold halves together if it’s a two-part mold, making sure they align correctly to avoid seam lines on your cast piece. You then melt your casting material—commonly metals such as gold, silver, or brass—in a crucible until it reaches its liquid state.

Carefully pour this molten material into the opening of your mold and allow it to fill every detail within the cavity. As it cools and hardens, patience is essential; removing it too soon can lead to defects or incomplete casts. Finally, after sufficient cooling time, remove your new jewelry piece from the mold and proceed with any necessary finishing touches such as trimming excess material or polishing.

How to Start Jewelry Casting?

Starting jewelry casting requires some initial investment in proper equipment along with a basic understanding of different casting techniques such as lost-wax casting or centrifugal casting. Begin by designing your desired jewelry piece using either traditional modeling techniques like sculpting wax models or modern methods involving CAD software for 3D printing prototypes.

Once you have an accurate model, create a robust mold using high-quality silicone rubber or another suitable material capable of capturing fine details without warping under heat stress. After preparing your mold and securing it properly if multi-part molds are used—heat-metal alloys like gold or silver until they reach their melting points before pouring them carefully into preheated molds designed specifically for optimal temperature distribution during cooling phases which helps avoid flaws due poor thermal conductivity resulting potential microfractures requiring additional repair work post-casting phase completion wherein participants engage detailed refinement processes including filing-sanding-polishing surfacing areas achieve flawless aesthetically pleasing end-product sufficiently valuable selling markets discerning customers appreciate craftsmanship involved producing customized finely-crafted artisan-jewelry pieces sought after globally fashion-conscious enthusiasts_VALIDATE_quality_process_ensure_each_step_meticulously_followed_important achieving_consistent_high_quality_output essential long-term_success_jewelry_casting_business endeavors aiming build reputation_reliability_expertise_field_remaining competitive ever-evolving industry dynamics market demands trends shift over_timeadapt_accordingly thrive offering unique value propositions differentiate yourself crowded marketplace leveraging creativity_innovation drive sustained growth profitability 사업부로써 유의미한 결과창출 기대합니다 .

Welcome to my jewelry blog! My name is Sarah and I am the owner of this blog.

I love making jewelry and sharing my creations with others.

So whether you’re someone who loves wearing jewelry yourself or simply enjoys learning about it, be sure to check out my blog for insightful posts on everything related to this exciting topic!