In the intricate world of jewelry design, the role of casting in jewelry design: an overview cannot be understated. This fundamental process bridges the gap between conceptual artistry and tangible masterpieces, playing a pivotal role in both modern and traditional approaches to creating fine adornments. Whether you are a seasoned jeweler or a novice enthusiast exploring the depth of this craft, understanding casting is essential to appreciating its impact on jewelry making.

Jewelry making, at its core, involves several meticulous steps-from initial sketches and material selection to crafting and finishing. Among these, casting stands out as a method that significantly influences design creativity, detail precision, and production efficiency. Traditionally revered techniques such as lost-wax casting have been integral in shaping iconic historical pieces. Meanwhile, contemporary innovations continue to evolve this ancient art form, enhancing both its practicability and artistic possibilities.

This article aims to take you through an enlightening journey that underscores the significance of casting in jewelry design. We’ll delve into its historical roots and examine how different cultures have contributed to refining casting methods over centuries. A comprehensive overview will also introduce you to various modern techniques and materials used today, as well as their ecological implications-bringing full circle the myriad ways in which casting continues to shape and redefine the world of jewelry design.

Historical Perspective of Casting in Jewelry Making

Early Origins and Evolution of Casting Techniques

The role of casting in jewelry design: an overview begins with understanding its ancient roots. The art of metal casting dates back thousands of years, with the earliest known examples originating from the Indus Valley Civilization around 3000 BCE.

Primitive societies initially employed basic techniques such as sand casting to create simple ornaments and tools. Over time, these methods evolved, leading to more refined processes like lost-wax casting, which allowed artisans to craft intricate designs by first shaping wax models that were subsequently replaced by molten metal.

Influence of Different Cultures on Casting Methods

Diverse cultures worldwide have left their mark on the development of jewelry casting techniques. For example, Egyptian jewelers around 2000 BCE perfected their own lost-wax method, enabling them to produce detailed pieces adorned with gemstones and enamel.

Similarly, Chinese artisans during the Shang Dynasty (circa 1600-1046 BCE) mastered bronze casting for both practical objects and decorative items. As these cultures interacted through trade and conquest, they exchanged knowledge and technologies that further enhanced the capabilities of jewelry makers across different regions.

Notable Historical Examples of Cast Jewelry

Throughout history, several iconic pieces highlight the mastery achieved by ancient craftsmen using casting techniques. The gold funerary mask of Tutankhamun discovered in Egypt exemplifies the sophisticated artistry possible through lost-wax casting.

Another prominent example is the Benin Bronzes from West Africa, which showcase exceptional skill in creating detailed sculptures through alloy casting methods developed by Edo artisans between the 13th and 19th centuries. These historical artifacts not only illustrate the technical advancements made but also underscore how integral casting has been to cultural expression in jewelry design.

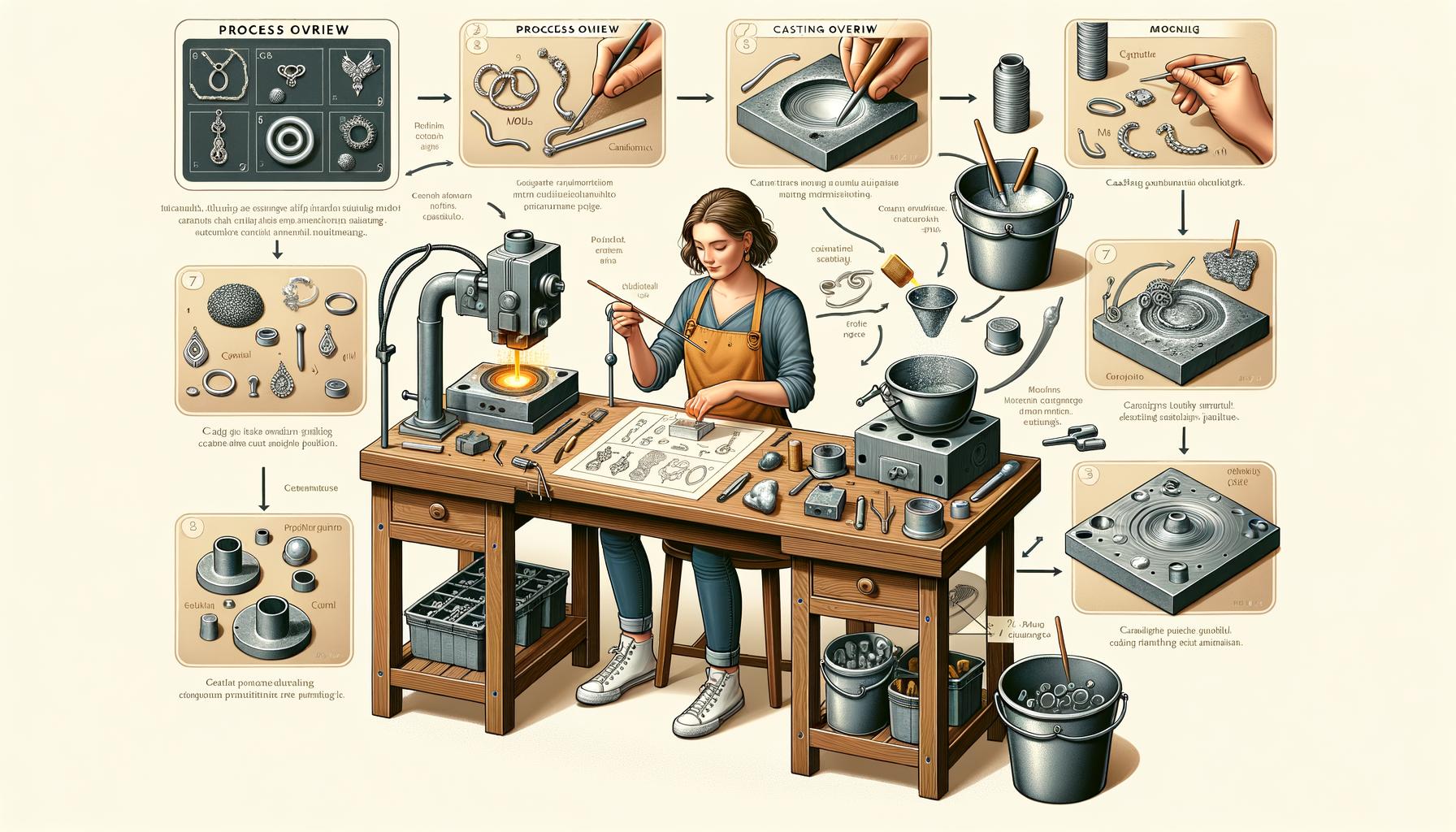

Understanding the Casting Process

Casting in jewelry design is a meticulous process that allows jewelers to create intricate and precise pieces. At its core, casting involves pouring molten metal into a mold where it solidifies into the desired shape. This method permits the reproduction of detailed patterns not easily achievable with other techniques. Various casting methods are employed; among them, lost-wax casting, sand casting, and centrifugal casting are prominent.

Lost-wax casting is perhaps the most ancient yet widely used technique. It begins with sculpting a model in wax, which is then encased in plaster or ceramics. Once hardened, the mold is heated until the wax evaporates (“lost”), leaving behind a cavity into which molten metal is poured.

Centrifugal force can enhance this method by ensuring an even distribution of metal within the mold. Sand casting uses compacted sand as the mold material, offering more breathability but less detail than lost-wax.

Each process involves several key steps: design conceptualization, mould creation, metal melting and pouring, cooling, and finishing (polishing or adding additional details). These steps demand precision and skill to ensure high-quality results. Technology’s advancements have refined these processes-for instance, computer-aided design (CAD) systems enable detailed 3D representations before any material work begins.

| Type of Casting Method | Description |

|---|---|

| Lost-Wax Casting | Sculpts wax models used to create molds; ideal for intricate designs. |

| Sand Casting | Utilizes compacted sand as a molding medium; less detail-oriented but flexible. |

| Centrifugal Casting | Applies centrifugal force to distribute molten metal evenly within the mold. |

A well-executed casting allows designers to be creative without compromising structural integrity or detail-a valuable contribution to “the role of casting in jewelry design: an overview.” Whether mass-producing items or crafting custom pieces, understanding these methods conveys both technical benefits and artistic freedom essential in modern jewelry making.

Materials Used in Casting

In the world of jewelry design, selecting the appropriate materials for casting is paramount to achieving both aesthetic and functional aspirations. The most common metals used in casting include gold, silver, and platinum. Gold, renowned for its luster and resistance to tarnish, is a perennial favorite.

Silver, while more prone to oxidation, offers a bright finish and affordability that makes it desirable across many market segments. Platinum, with its excellent durability and hypoallergenic properties, is chosen for high-end pieces meant to withstand daily wear.

When choosing materials for casting, several considerations come into play. Durability is crucial as it determines how well the piece will hold up over time.

Malleability affects how easy it is to work the metal into intricate designs during both the conception phase and further refinement post-casting. Cost also plays a significant role; while precious metals like gold and platinum bring an air of luxury, they substantially increase production expenses compared to more affordable options such as silver or even alternative metals like bronze or brass.

Modern innovations have expanded the repertoire of materials available for casting significantly. Jewelers today can opt for eco-friendly alternatives that cater to increasing consumer demand for sustainability.

Recycled metals and lab-created alloys not only reduce waste but often come with enhanced properties favorable for both artisanship and wearability. Additionally, breakthroughs in technology have introduced composite materials that merge traditional aesthetics with modern-day functionality-offering exciting new frontiers in the role of casting in jewelry design: an overview of these advancements reveals an ongoing evolution towards blending beauty with ethical responsibility.

- Gold

- Silver

- Platinum

- Recycled Metals

- Lab-Created Alloys

- Composite Materials

These material choices help enhance the final product’s value proposition by balancing beauty with practicality-a delicate equilibrium every designer must strike when engaging in their craft. By staying aware of innovations and material science developments within the industry, jewelers can continue pushing boundaries while adhering to ethical practices-a combination that promises longevity not just for their creations but also for their reputation among discerning consumers.

Technology and Innovations in Casting

Recent advances in technology have revolutionized the way jewelers approach casting, magnifying creative possibilities while streamlining production. One of the most impactful innovations is the integration of 3D printing and computer-aided design (CAD) in jewelry making. These technologies allow designers to create highly detailed and intricate models with unprecedented precision.

CAD enables the visualization of complex designs that can be adjusted and perfected before any physical materials are engaged. Once a design is finalized, 3D printing can produce prototypes or even direct castable patterns, significantly reducing both the time and material costs involved.

Modern advances in casting techniques go beyond just digital tools. Innovations such as laser welding and induction melting have improved the quality and efficiency of metalwork. Laser welding, for example, offers precise control over heat application, ensuring cleaner joins without compromising the integrity of the metal.

This level of precision is crucial when dealing with intricate or delicate pieces often found in high-end jewelry design. Similarly, induction melting provides a more uniform heating process compared to traditional methods, reducing inconsistencies that could impact the final product’s durability.

Looking ahead, future trends in jewelry casting promise even more exciting developments with far-reaching implications for both designers and consumers. For instance:

- Sustainable practices: Developments focused on eco-friendly materials and methods are gaining traction as consumers become more aware of environmental issues.

- Smart materials: Research into advanced alloys that change properties under different conditions can lead to innovative designs previously thought impossible.

- Automation: Advanced robotic systems may handle repetitive or dangerous tasks with greater speed and precision than human workers.

These technological advancements not only enhance productivity but also empower designers by expanding their creative horizons. The role of casting in jewelry design: an overview would be incomplete without acknowledging how these modern innovations continue to shape an already dynamic field, pushing boundaries while maintaining craftsmanship’s timeless allure.

The Role of Casting in Jewelry Design

Casting plays a pivotal part in the evolution of jewelry design, fundamentally shaping how intricate and complex pieces can be brought to life. With casting techniques, designers are not restricted by the limitations posed by other methods; this freedom allows for the creation of more innovative layouts and patterns.

For instance, lost-wax casting enables artisans to sculpt highly detailed elements that could be nearly impossible to achieve through simple handcrafting. This method eliminates many constraints traditionally encountered when translating a designer’s vision into a tangible product, thus fostering increased creativity and the emergence of avant-garde designs.

The role of casting in jewelry design: an overview also underscores its benefits for both mass production and custom-piece manufacturing. When it comes to producing multiple units of a particular item, such as replicas of a successful design or uniform sets for collections, casting offers unparalleled efficiency and consistency.

Each piece cast from the same mold will carry identical dimensions and qualities, maintaining brand integrity and allowing businesses to meet considerable consumer demand effectively. Conversely, custom jewelry designers benefit from casting’s ability to fine-tune every minute detail for bespoke items tailored specifically to individual client specifications.

Iconic designs in jewelry history owe their creation often to advanced casting techniques. Take, for example, the legendary Fabergé eggs produced by Peter Carl Fabergé in imperial Russia during the late 19th century.

These exquisite masterpieces could only reach their renowned level of detail and splendor due to precise casting methods combined with traditional artistic skills. Similarly, modern examples abound where contemporary artists use sophisticated casting technologies alongside digital fabrication tools like CAD modeling and 3D printing to generate astonishing works that push boundaries while retaining aesthetic excellence.

| Application | Benefit |

|---|---|

| Lost-Wax Casting | Enables intricate detailing |

| Mass Production | Ensures uniformity across pieces |

| Custom Designs | Allows for fine-tuning specific details |

Challenges and Solutions in Casting

Casting, while a cornerstone of jewelry design, comes with its own set of challenges that designers must navigate to achieve exceptional results. One common issue faced during the casting process is shrinkage, where the metal contracts as it cools, potentially distorting intricate designs or creating gaps.

To combat this problem, jewelers often use advanced mold-making techniques that account for expected shrinkage and meticulously monitor cooling rates. Additionally, selecting alloys with reduced shrinkage tendencies can further mitigate these issues, ensuring that the final product closely matches the original design specifications.

Another prevalent challenge in casting is porosity, which occurs when air bubbles become trapped within the molten metal as it solidifies. Porosity can weaken the structural integrity of the jewelry piece and detract from its aesthetic appeal. Jewelers have developed various techniques to address this concern, such as vacuum casting and centrifugal casting methods.

These approaches help remove air bubbles by using controlled environments or forces that push molten metal into every crevice of the mold. Furthermore, modern innovations like pressurized chambers during casting significantly reduce the occurrence of porosity, resulting in more reliable outcomes.

The role of casting in jewelry design: an overview would be incomplete without discussing troubleshooting techniques for unexpected defects such as surface roughness or inclusions. Surface imperfections may arise due to impurities in the metal or inconsistencies within the mold itself. Jewelers often employ meticulous cleaning processes for both metals and molds before casting begins to minimize these risks.

Moreover, advanced post-casting finishing techniques like polishing and laser treatments are used to perfect surfaces and enhance detail clarity. Keeping abreast of advancements in tools and technology also empowers jewelers to continually improve their casting practices, making high-quality pieces consistently achievable.

- Shrinkage mitigation through advanced mold-making techniques

- Porosity reduction via vacuum or centrifugal casting methods

- Surface perfection using post-casting finishing techniques

- Continual learning about new tools and technologies

By addressing these challenges head-on with innovative solutions and detailed craftsmanship, artisans ensure that each cast piece not only meets aesthetic standards but also possesses enduring quality-a testament to their expertise in navigating the complexities inherent in jewelry design.

Ecological and Ethical Considerations in Casting

Environmental Impact of Traditional Casting Methods

The environmental footprint of traditional casting methods is significant, often involving high energy consumption and the emission of harmful substances. These processes typically require melting metals at extremely high temperatures, which necessitates substantial amounts of energy. Additionally, materials like investment plaster, used in molds, are not always biodegradable, contributing to landfill waste.

The role of casting in jewelry design: an overview cannot be complete without addressing these ecological repercussions. The use of chemicals such as slurry and flux can lead to hazardous waste if not properly managed.

Ethical Sourcing of Casting Materials

Another critical aspect is the ethical sourcing of materials used in casting. Many precious metals like gold and silver come from mines that have a notorious history for poor labor conditions and negative environmental impacts.

Conflict-free sourcing has become a focal point within the industry, aiming to ensure that the metals used do not fund violence or human rights abuses. Jewelers now frequently turn to recycled metals as a more ethical alternative, re-purposing existing metal resources to produce new designs without further depleting natural reserves.

Industry Movements Towards Sustainable Practices

The jewelry industry is increasingly adopting sustainable practices to mitigate these issues. Innovations such as eco-friendly investment materials are being developed to replace traditional options that have a more significant ecological impact.

Furthermore, advancements in recycling technologies make it easier for jewelers to reclaim metal from old pieces or manufacturing scraps for use in new creations. There’s also a rising trend toward transparency where consumers can trace the journey of their jewelry pieces from mine to market, ensuring they align with environmental and ethical standards.

Casting Versus Other Jewelry-Making Techniques

Casting is a vital process in the jewelry-making world, but it’s not the only method to create stunning pieces. Comparing casting with other techniques like hand fabrication, engraving, and setting can highlight its unique benefits and limitations. Each method offers different advantages that cater to varying demands for style, complexity, and production scale.

Hand Fabrication

Hand fabrication involves manually shaping metal sheets or wires using tools such as saws, files, and soldering equipment. This technique allows artisans to put a personal touch on each piece, offering unmatched craftsmanship and uniqueness.

However, hand fabrication can be time-consuming and labor-intensive compared to casting. While casting enables the creation of intricate designs in less time by pouring molten metal into molds, hand fabrication excels in detailed custom work which might be difficult or impossible to achieve through casting alone.

Engraving

Engraving is another fascinating jewelry-making technique where a skilled artisan carves intricate patterns or symbols directly onto the surface of the metal. This method is commonly used for adding decorative details or personalizing items like rings and bracelets. Although enhancing aesthetic appeal significantly, engraving cannot replace casting for creating complex three-dimensional forms. Instead, it often complements cast pieces by adding fine detail that brings out the design’s character even more vividly.

Comparison With Casting

The role of casting in jewelry design: an overview would be incomplete without acknowledging how it enables mass production while maintaining high-quality standards. Unlike hand fabrication or engraving which require significant manual skill for each piece made individually, casting allows jewelers to replicate designs precisely and efficiently. For instance, in producing engagement rings or watches where uniformity is critical across multiple units, casting provides consistency without sacrificing innovation or beauty.

Overall, although each technique has its distinct strengths that appeal differently based on desired outcomes-whether it’s the bespoke allure of hand-fabricated pieces or the precision replication achievable through casting-understanding these differences empowers designers to choose the best method suited to their artistic vision and practical needs.

Practical Guide

Embarking on the journey of cast jewelry making can be both exciting and fulfilling for any aspiring jeweler. The first step in the process is assembling the required tools and equipment essential for casting.

At a minimum, you’ll need a wax carving kit, a mold frame, casting investment (a type of plaster), a kiln or torch for melting metals, and a centrifugal casting machine or vacuum casting system. While these tools may seem daunting at first, familiarity with them will enhance your understanding of the role of casting in jewelry design: an overview that reveals its transformative potential.

Setting up your small-scale casting workshop should involve careful consideration of space and safety. Adequate ventilation is crucial as it mitigates exposure to fumes generated by melting metals. A sturdy workbench equipped with proper lighting will facilitate precise work on wax models and molds.

It’s also beneficial to allocate specific storage solutions for different metals and alloys to keep materials organized and easily accessible. Investing in safety gear such as heat-resistant gloves, goggles, and aprons cannot be overstressed; ensuring personal safety allows you to focus wholeheartedly on your craft without risk.

For beginners interested in mastering casting techniques, numerous resources are available to guide you through the learning curve. Many online platforms offer tutorials ranging from basic introductions to advanced projects. Enrollment in local workshops or classes can provide hands-on experience under expert supervision-an invaluable asset in honing your skills. Additionally, joining forums or social media groups focused on jewelry casting can connect you with like-minded individuals who share tips, troubleshooting advice, and inspiration.

| Essential Tools | Safety Equipment |

|---|---|

| Wax Carving Kit | Heat-Resistant Gloves |

| Mold Frame | Goggles |

| Kiln or Torch | Aprons |

| Centrifugal/Vacuum Casting System | Adequate Ventilation Setup |

Conclusion

In summary, the role of casting in jewelry design: an overview reveals the multifaceted impact this technique has had on both historical and contemporary craftsmanship. From its humble beginnings in ancient cultures to the technologically advanced methods of today, casting remains an indispensable part of jewelry-making. This process allows designers to bring highly intricate and complex designs to life, meeting aesthetic and functional needs that may otherwise be challenging to achieve through other techniques.

Casting’s adaptability offers significant benefits whether for mass production or custom pieces. For instance, mass-produced items benefit from consistent quality and repeatability, ensuring each piece meets exact standards. In contrast, custom-designed pieces take advantage of casting’s capability to handle complex and detailed work, allowing for personalized creations that stand out. Iconic examples in history demonstrate how casting has allowed artists to push the boundaries of design creativity.

As the industry moves forward, it navigates a balance between honoring traditional methods and embracing modern innovations. Technologies such as 3D printing and computer-aided design (CAD) have opened new horizons for what can be achieved through casting. Additionally, an increased awareness about environmental sustainability is driving significant changes in material choices and ethical sourcing practices. Collectively, these advancements ensure that casting will continue to play a vital role in the evolution of jewelry design for years to come.

For those inspired by this journey through time and technology, now is indeed a promising time to dive into the world of casting. Whether you’re an aspiring jeweler or an accomplished designer looking to expand your repertoire, exploring the depths of casting techniques can greatly enhance your creative toolkit.

So pick up that wax model or fire up that 3D printer-it’s time to let your imagination transform raw material into wearable art, leveraging all that we have learned about this age-old yet ever-evolving craft.

Frequently Asked Questions

What Is Casting in Jewellery?

Casting in jewelry refers to the process of creating intricate metal shapes by pouring molten metal into a mold, which is often made from a wax model. This technique allows for the precise reproduction of detailed designs and facilitates the mass production of jewelry pieces.

Once the metal cools and solidifies, the mold is removed, revealing the final piece which can then be polished and finished.

Which Casting Process Are Used by Jewellers?

Jewellers typically use several casting processes such as lost-wax casting, centrifugal casting, and vacuum casting. Lost-wax casting involves creating a wax model that is encased in a refractory material to form a mold; once heated, the wax melts away, leaving a cavity for the molten metal.

Centrifugal casting uses centrifugal force to push molten metal into molds quickly and under pressure, ensuring fine detail and minimal air bubbles. Vacuum casting employs a vacuum to draw molten metal into the mold with precision.

How Do You Make Jewellery Casting?

To make jewelry casting, one begins with creating or selecting a design that will be rendered in wax or another easily shaped material. This wax model is then surrounded by refractory investment material within a flask and heated to burn out the wax, forming an empty mold cavity.

Molten metal is poured or injected into this cavity using either gravity, centrifugal force, or vacuum pressure. After allowing it to cool and harden, the investment material is broken away to reveal the cast piece, which undergoes further finishing processes like polishing and setting any stones required by the design.

Welcome to my jewelry blog! My name is Sarah and I am the owner of this blog.

I love making jewelry and sharing my creations with others.

So whether you’re someone who loves wearing jewelry yourself or simply enjoys learning about it, be sure to check out my blog for insightful posts on everything related to this exciting topic!